Good quality pellets have several benefits: reduced waste, less segregation in the feed, improved palatability and shorter eating periods. Also animal performance and feed efficiency can benefit from pelleting the feed.

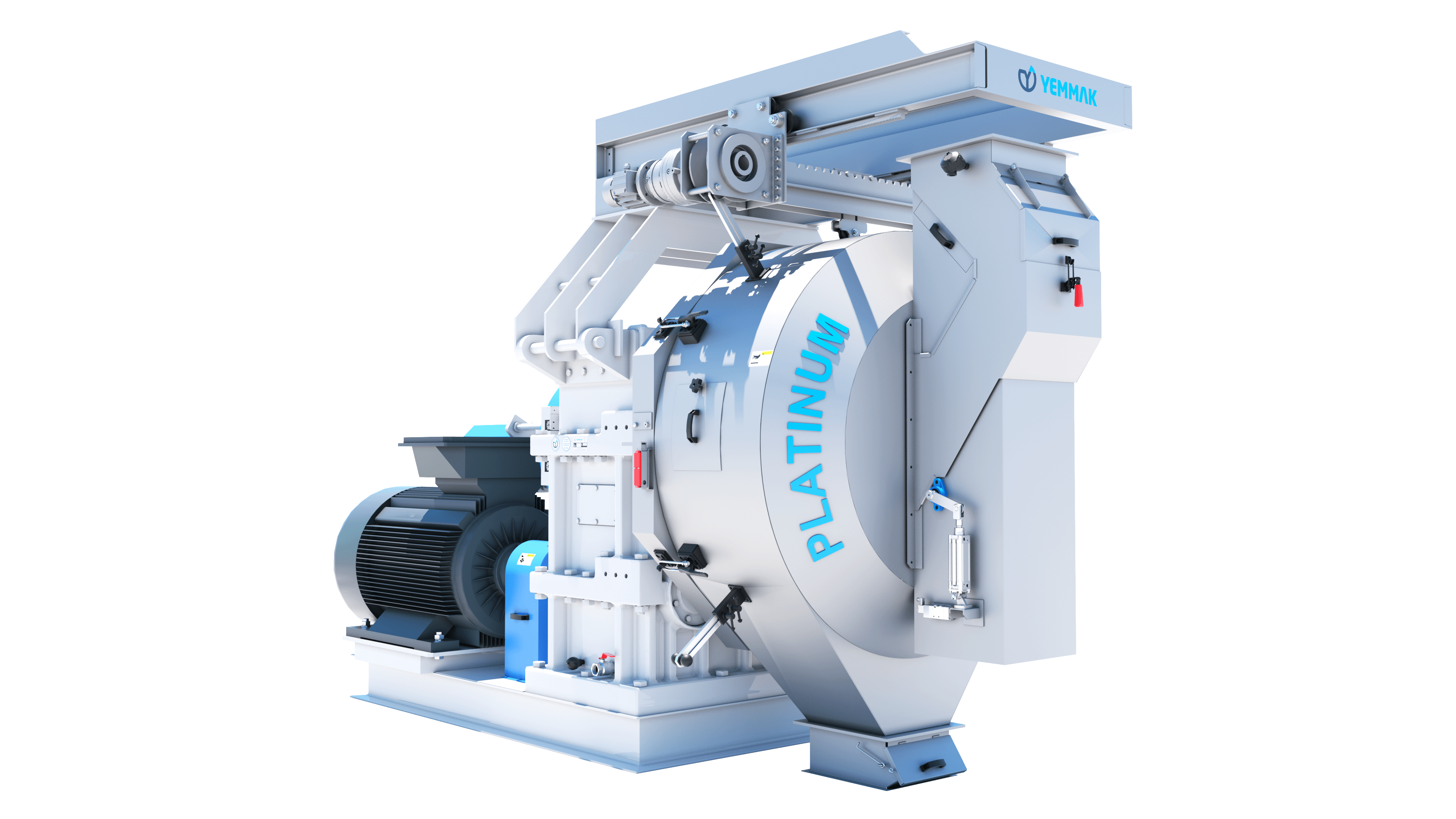

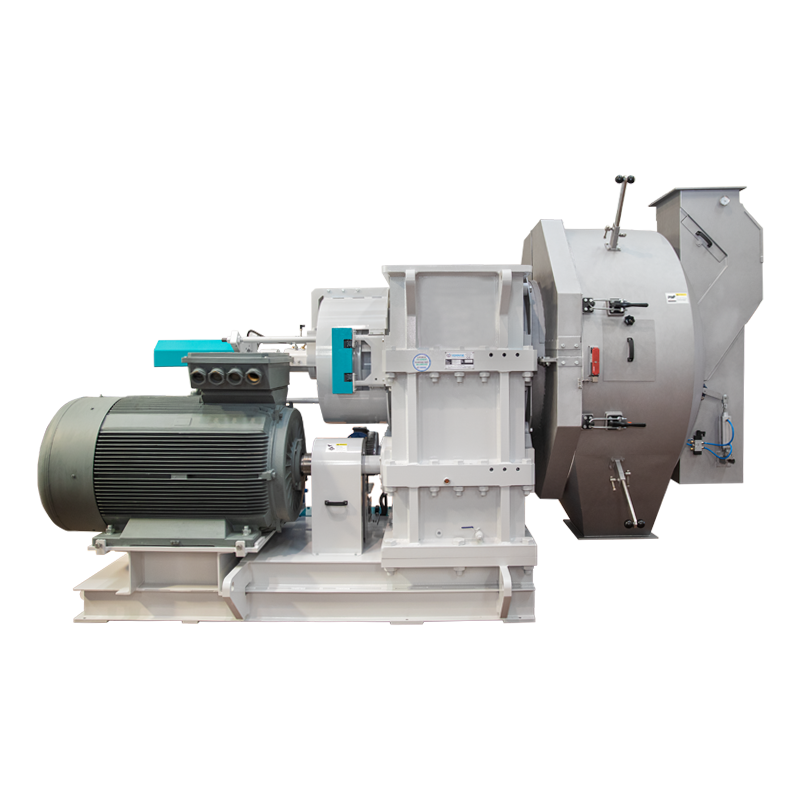

Yemmak is the producer of The Platinum series pellet mills which offer the pelleting capacity between 20 to 45 tph. * ( actual capacity depends on the formulation and the die specifications).

The platinum series pellet mill comes with, from 900 mm to 1144 mm diameter dies, having the width between 230 mm to 400 mm. The drive motor options ranging from 315 kw to 560 kw gives the opportunity of the highest capacity , quality and energy savings ,even with the difficult to pellet formulations.

The Platinum series pellet mills get their power from the specially designed/ machined high efficiency gear set. The two-stage precise gear set enables strength and durability to the machine, while guarantee the highest pellet quality and capacity.

The gearbox body offers the flexibility to drive the pelletmill with different drive motor options.

The pellet mill is equipped with a “forced oil circulation/lubrication system” supported by a forced air cooled heat exchanger and temperature /flow sensors , to guarantee the supply of exact amount oil to the 7 different lubrication points. This is ensures problem free operation for years.

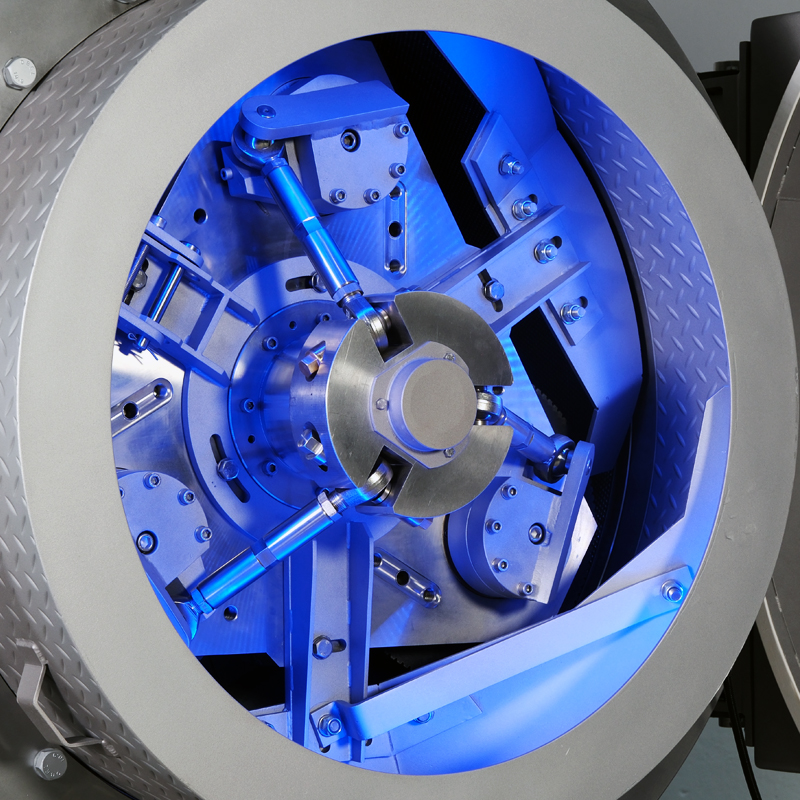

Die and rollers are made of alloy steel and vacuum hardened and produced in Germany. The different roll and die specifications are possible to obtain the highest capacity and quality with the different raw materials.

AUTOMATIC ROLL GAP ADJUSTMENT SYSTEM (ARGAS®)

The PT 1200 pellet mills having the three roll design to ensure more uniform stress distribution on the die and can be equipped with the optionally available “automatic roll gap adjustment system”(ARGAS®).

The ARGAS is driven by a hydraulic cylinder which has embedded linear encoder in it to measure the gap with the extreme accurate. Specially designed valve block and hydraulic power unit which having several electronics and hydromechanical sensors and safety valves are constantly monitors the operating parameters and whenever they exceed the safety limits the ARGAS acts automatically and open the rolls to help to protect the machine.

In case of jamming or routine maintenance, this system opens the rolls in seconds and allows the operator to clean the die and run the pellet mill again in very short time. This dramatically reduces maintenance and downtimes.

The pellet mill has double skin pellet chamber which is fabricated in stainless steel. The double skin design helps to reduce the condensation at the inner surface of pelleting chamber which can cause the pastry like material build up on the inner surface with times. Which can cause jamming, incase of falling in between the roll and the die.

For the cold climates the hot air or electric surface heating systems are also optionally avaible.

The inlet chute of the pellet chamber is equipped with the easy accessible permanent magnet to catch the tramp metals and the pneumatically operated overload valve.

The pellet chamber is equipped with the 3 pellet knife which are manually adjustable and outtrack. Optionally, pneumatically operated knife outtrack mechanism is possible.

Poultry feed production is becoming more important day by day as the population...

Discover

Yemmak conducts facility layout, machinery design, production, logistics and implementation operations in bran pelleting facilities.

Discover

Beet pulp is a by-product of sugar factories offered for animal consumption.

Discover

Poultry and livestock droppings are mixed in ponds and converted into ...

Discover

Follow Yemmak Quality

on Social Media!

You can trust us because we don’t have to rely on others. We

are offering all manufacturing, assembling, testing and after sales services from

a single source by proven Yemmak quality!

Follow Yemmak and keep up with us on social media to be

informed about our ongoing projects and the latest news!

Be aware of the latest developments with our corporate e-newsletter Yem'max! From current projects we have implemented to industry trends; You can reach all the news from in-house news to the information of our advanced technology machines with one step.

Subscribe