Beet pulp is a by-product of sugar factories offered for animal consumption. Beet bagasse is the cheapest source of roughage that is easily digestible and eagerly eaten by dairy cows and feeder cattle.

Sugar beet pulp is obtained from sugar beet by diffusion after sugar extraction. At the end of the extraction process, the sulfur is removed and the bagasse is obtained after the squeezing process. It provides a 30 percent increase in milk yield. It is easy to digest, helps with straw consumption and contains 8 percent protein.

There's plenty of protein in the beet bagasse. For this reason, the bagasses are used as a protein source and as a protein supplement. It is almost impossible to meet the protein needs of cows that give plenty of milk without using bagasse. Because the bagasse contains around 20 to 40 percent digestible protein. Despite being high in protein, they are cheaper than other feeds.

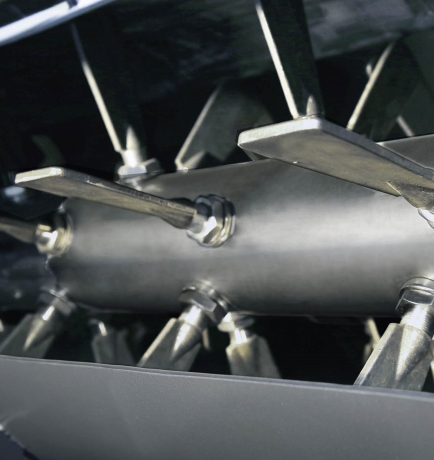

Used as raw material in feed mills, beet bagasse is pelleted to provide logistics and storage advantages. The diameter of the beet bagasse pellets produced by Yemmak pellet mills can be from 8 to 14mm.

Sugar beet pulp pelleting plant is developed by Yemmak engineers, with the optimum design according to customer needs.

Processes

Cleaning & Sieving

During the cleaning and sieving process, foreign objects are removed from the raw material.

Discover

Conditioning & Hygienization

Conditioning is the step before pelleting during feed processing.

Discover

Cooling & Drying

Cooling machines produced by the Yemmak's expert engineers are used for cooling pellet feed, processed granular products, ground feed and rendered feed in the pet food facilities, chemical facilities, fertilizer production factories, and biomass

Discover

Conveying

Raw material transportation systems come with various types of equipment such as screw conveyors, chain conveyors and elevators.

Discover

Personalized Appointment Form

You can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time!

Industries