Importance and Benefits of Rendered Products in Poultry Nutrition

The poultry industry has seen major changes over the past 50 years across the globe. Consumption of poultry and poultry products has increased dramatically during this time, and the evolution of the industry has led to advances in nutritional formulation with the introduction of new ingredients and technology. Formulas were created via computer, digestible amino acid-based formulas were preferred instead of total protein-based formulas, and various micronutrient sources were included in the formulas. As a result, costs for the poultry industry have been reduced and poultry performance has been maximized.

The availability of various rendering by-products has greatly benefited the modern poultry industry. But due to changes in consumer choice and welfare standards, the industry needs to address the challenges of using rendering products so that these beneficial products can continue to be used.

Use of Rendered Products in Poultry Feed

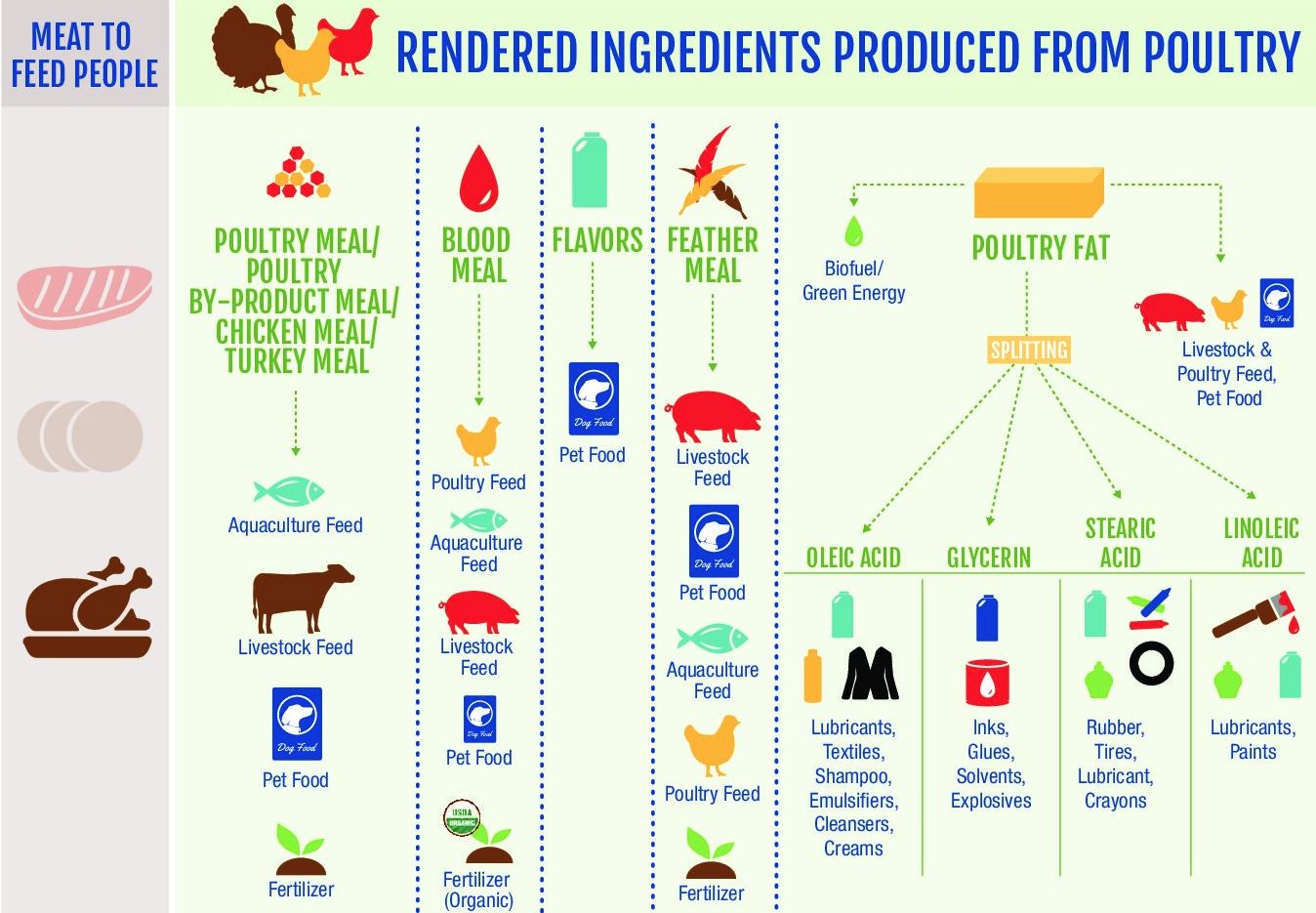

Animal proteins and some rendered fats have been used globally for many years in poultry feed. In fact, all protein and fat sources have been used and continue to be used in significant amounts all over the world, taking into account their relative values compared to other protein sources (e.g. soybean meal). Products currently being utilized include ruminant and poultry meat meal, as well as blood products from these proteins, rendered fat and feather meal. In addition, today, "whole hen meal" made from spent laying hens has begun to be produced. Each of these products has been successfully used in various rations given to broilers and turkeys that need high relative protein compared to layers.

Animal proteins and fats provide the nutrients needed by poultry at more affordable prices than competing products. Therefore, the idea of replacing some of the soybean meal in poultry rations with animal protein products to improve performance has attracted attention in the industry. The oligosaccharide portion of soybean meal produces some harmful effects on poultry. This is thought to be due to a substance found in the undigested portion of the product. The addition of animal protein can improve performance over standard vegetarian diets. While these results may be due to high levels of limiting amino acids, they may also be explained by the reduced amount of poorly digested carbohydrates in soybean meal. Studies suggest that almost half of the protein source in the formula can be obtained from mixed by-products. While each product has different nutritional content and potential values, most are excellent sources of energy or high-quality protein. They also contain highly available phosphorus and other minerals.

Image – Rendered Ingredients Produced From Poultry

Practical Use of Fat in Poultry Rations

The use of fat in poultry feed and the effects of fat addition are well known in the industry. A minimum level of fat (usually 1%) is fixed in the meal for several reasons; the main reason is to provide sufficient amount of linoleic acid. It also helps to reduce dust levels of feed, lubricates equipment and improves palatability of feed. Addition of this amount is usually done regardless of cost. Levels exceeding one percent in the formulation are mostly used to increase growth rate and feed efficiency and are directly related to feed costs.

Different fat sources are available for poultry from the rendering industry. Primary sources are poultry fat, tallow, yellow grease and blends. Apart from these, vegetable fats such as sunflower oil, soybean oil or palm oil are also used to a great extent. Usually these fats are expensive compared to rendered products. So less vegetable fat should be used for the same cost; this means lower metabolizable energy (ME) diets.

Inclusion of rendered fats in poultry feed has many advantages, such as:

- Concentrated source of energy and the main method of increasing the energy content of diets

- Increased growth rates, feed efficiency, and palatability of feeds

- Decreased feed intake and dustiness of feeds

- Good source of linoleic acid

- Lubrication for equipment in feed mills

- Possible slow gut transit of other feeds resulting in increased digestibility

- Possible “extra-caloric” effect that may be more cost-effective than other energy sources

- Concentrated feeds that decrease transportation costs for feed delivery

- Use of higher levels of fat that could negate the effects of pelleting.

However, there are some concerns that should be noted with fat utilization, including:

- Measurement of ME content can be somewhat difficult

- Potential for rancidity

- Equipment needs relative to fat additions must be adequate

- Poor digestibility of saturated fats by the young bird.

One of the major concerns with fat usage is the actual ME value that should be assigned to each fat source. This number is often difficult to determine in practical sense and may have little value in diets (Table 1-2). The energy content analysis of the fat is usually done by substituting a portion of the ration fed in the ME calculation. This is an indirect method. Also, fat may have an "extra-caloric" effect, whereby it affects the nutrient availability of other ingredients. For example, the addition of fat increases the digestibility of meat and bone meal (MBM). This would explain why some reported ME values are greater than the gross energy values of fat.

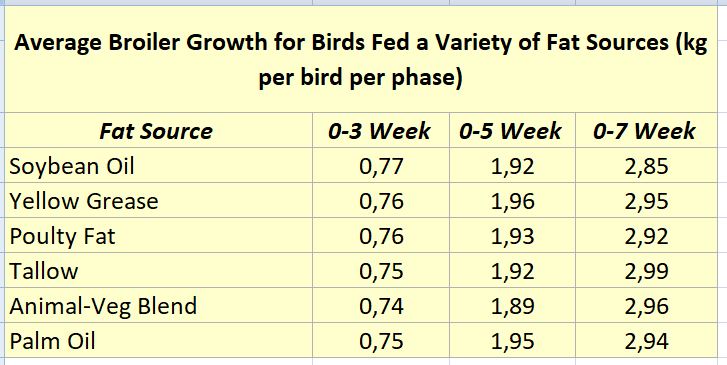

Table 1 – Average broiler growth for birds fed a variety of fat sources

Studies in poultry rations have shown that unsaturated vegetable oils have a higher ME value than rendered fats or products with high free fatty acid content. However, no difference was observed in the performance parameters of the different fat sources when fed as a portion of a complete ration (Table 1-2).

Studies in poultry rations have shown that unsaturated vegetable oils have a higher ME value than rendered fats or products with high free fatty acid content. However, no difference was observed in the performance parameters of the different fat sources when fed as a portion of a complete ration (Table 1-2).

Increasing dietary fat improves feed efficiency, but may also lead to increased fat deposition. In one experiment, turkeys were fed a diet containing a standard amount of fat and a diet containing 50% more fat. Growth rate in turkeys ranged from 11.5 kg to 13.3 kg, with significant differences in feed conversion ratio (1.55 versus 1.1). In these studies, while birds decreased feed intake in response to the higher energy diets, overall energy was higher with additional energy coming from fat additions.

Use of Animal Proteins in Poultry Rations

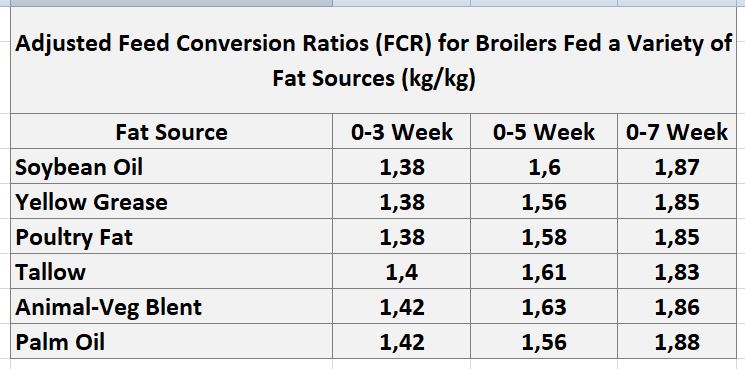

Animal proteins obtained from the non-edible portion of cattle/poultry processing include meat meal, MBM, poultry by-product meal, feather meal and blood meal. Products may vary according to various nutritional inputs and the proportion of bone. Meat-based meals range from 50% to 65% protein and can contain up to 5% available phosphorus as well as different nutrients. Feather and blood meals can have 80% crude protein, though the amino acid profile of the protein is not well-balanced.

Image – Poultry Rendered Products – Blood Meal & Feather Meal

Protein from many of these products is highly digestible and cost-effective. Phosphorus is generally thought to be highly available although phosphorus from bone meal sources has been shown to be slightly less available than from dicalcium phosphate. However, more recent data show that there is no difference in utilization of phosphorus from animal protein meals or dicalcium phosphate.

Use of rendered proteins in poultry feed has many advantages. Some of the benefits of their addition are:

- Competitive cost-wise relative to vegetable protein sources thus reducing total diet costs in most cases

- Source of high quality protein that is highly digestible in most cases

- May help balance out amino acid needs

- Provides a small increase in growth rates over vegetable protein-only diets in many cases

- Excellent source of highly available phosphorus and other minerals.

Some concerns that should be noted with utilization of rendered proteins include:

- Poor quality control could result in decreased amino acid digestibility

- Proper formulation methods must be used for most effective use

- Variation of product due to material mix and/or processing methodology.

Use of rendering proteins has been limited in the past for various reasons. In old studies, it has been observed that the problem called growth depression (decrease or stop in growth) occurs when protein use exceeds certain limits (e.g. 7.5%). This is due to the reduced digestibility of many products relative to soybean meal. Older lab data show that there is almost 10% less digestible lysine in MBM than in soybean meal. Thus, as the levels of MBM increased in the diet, the level of lysine available for use by the bird decreased. Although this deficit is tried to be covered with various safety factors, it is inevitable that amino acid deficiency will develop and growth rate will decrease or stop as a result. It is possible to eliminate these problems with a more digestible formulation.

Image – Poultry Rendered Products – Meat and Bone Meal (MBM)

Rendering proteins are heavily used in most broiler and turkey diets. The most cost-effective additions are achieved by a computerized system selecting from a variety of available animal protein meals. Including multiple protein sources reduces cost, improves nutrient balance and decreases nitrogen excretion.

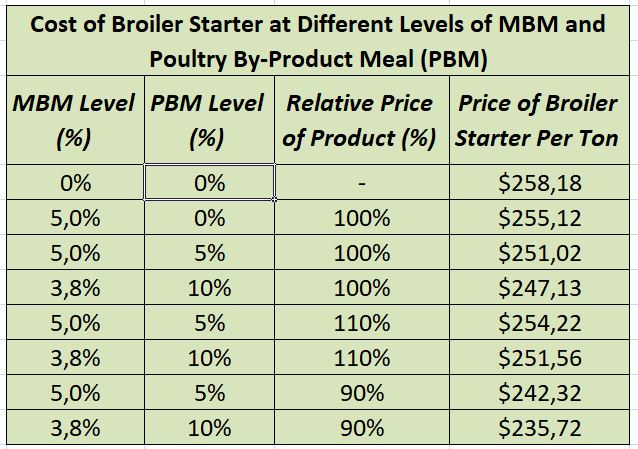

Ruminant origin MBM is often the most cost-effective source. This is followed by feed grade poultry by-product meals. These two products are added to recipes as a source of protein and phosphorus, the protein/energy amount of poultry by-product meal is generally higher. Based on a digestible formulation and focusing on animal growth, the upper limit of these additives can easily exceed 10%, but generally cost efficiency is considered. If a digestible amino acid-based formulation is not going to be made, product digestibility should still be considered and if there are significant differences compared to soybean meal, the upper limit of additive ratio should be determined. Given the available data, all poultry diets should be formulated on a digestible basis in the future. The effect of additions of MBM and poultry by-product meal on diet cost in various scenarios can be seen in Table-3.

Table 3 – Cost of broiler starter at different levels of MBM and PBM (Poultry By-Product)

In summary, rendered products provide valuable and important sources of highly available energy, protein and minerals that should continue to be utilized by all aspects of the poultry industry.