Energy saving in compound feed mills

"The energy saving measures could be different for each country depending on specific conditions such as energy price and energy regulation. Moreover, in a particular country, each feed mill should be considered like a unique case because the energy efficiency solutions proposed for a feed mill could not be the most suitable for another feed mill. In order to improve its energy efficiency, a feed mill can implement techniques which are described in Best Available Techniques reference documents. Some examples can be optimized only with steam adjustment and some of them need high precision control system with speed control devices. However, with small touch it is easy to reduce energy 5% and with a well-planned plant investment energy can be saved approximately 20%.”One of the most important expense items in compound feed mills is energy costs. This is one of the important factors that causes pressure on feed costs (after feed raw materials), which is a very important issue for animal breeders today. In addition, energy consumption is frequently on the agenda as an extremely important issue in terms of global climate change. Many professional companies are now focusing on goals such as reducing carbon emissions, reducing environmental footprint and achieving sustainable production. All these reveal the importance of energy saving in all kinds of production, including feed mills.

While the new facilities to be established are often established with maximum energy savings in mind, existing factories can also provide significant energy savings with various measures that can be taken and improvements in the production process.

Mahmut Tatlıdil, Business Development Assistant Director at Yemmak, one of the important representatives of the feed processing technologies sector, states that energy savings that can be achieved in a well-planned factory can reach up to 20 percent.

Tatlıdil explained energy savings in compound feed facilities and what needs to be done for readers of our magazine in 8 questions.

What is the meaning of energy saving in feed plants and why is it important?

Energy is one of the most critical input resources in the manufacturing industries. In most cases, energy cost outweighs the costs of other resources such as raw material, labors, depreciation and maintenance. The key point of energy cost is changeable and has effect on feed cost. The aim of the animal feed production is to mix, as homogenous as possible, various raw materials and components to provide a balanced nutrition to food producing animals with the best conversion performance. As basic principle we cannot change whole system but touches of components are clear. Actually energy is not only from electrical sources, steam and compressed air is also energy sources and consuming points.

The shape, size, mixing and pelleting are changing effectiveness, if market doesn’t need to use pellet form, system should change dynamics and reduce the consumption. This is just an example.

What is the estimated amount of energy consumption used at different production capacities in compound feed mills?

Actually from 4 to 40 Kwh/ton is possible to observe, concerning the influence of grain mechanical properties on wheat grinding energy requirements. The investigations were carried out on 10 wheat varieties (grain moisture was 15%). The results showed that the specific grinding energy ranged from 6 to 10 Kwh/ton. Increase in fat concentration in feed material from 2 to 5.5% reduces energy consumption during pelleting by 30%. In general, the specific energy required for pelleting (i.e., energy consumed by the pellet mill motor) may range from 4 to 40 kWh/t. It is estimated that steam conditioning to increase the temperature from 27 to 80 °C consumed about 26 kWh/t. Steam add in its pelleting operations improves pellet durability. Added steam provides heat and moisture and it also helps to reduce energy consumption during pelleting.

Average values are for pelleting process with steam and electric on ruminant feed 20-24 kWh/ton, poultry feed 10-12 kWh/ton and pork feed 15-17 kWh/ton.

High capacity plants save more energy than lower capacity plants. For sure the lion share is pelleting and grinding lines but bigger grinding chamber consumes lower energy. The formulations and steam addition can have a big impact on the amount of electricity used on the presses but this is not considered in detail in this article. The use of fat in the mix can help reduce press electrical energy, but at a cost, as can the use of pelleting aids – we’ve tried some and not found sufficient savings to pay for their inclusion but that doesn’t mean they don’t work at all. Reducing physical quality and grinding coarser can reduce energy consumption but at what cost to complaints and reputation – it’s a constant balance.

Approximately how much energy can be saved in a feed plant with an appropriate energy management plan?

Each country has these typical production characteristics. The energy saving measures could be different for each country depending on specific conditions such as energy price and energy regulation. Moreover, in a particular country, each feed mill should be considered like a unique case because the energy efficiency solutions proposed for a feed mill could not be the most suitable for another feed mill. In order to improve its energy efficiency, a feed mill can implement techniques which are described in Best Available Techniques reference documents. Some examples can be optimized only with steam adjustment and some of them need high precision control system with speed control devices. However, with small touch it is easy to reduce energy 5% and with a well-planned plant investment energy can be saved approximately 20%.

Which processes/machines have the highest energy consumption in a feed plant?

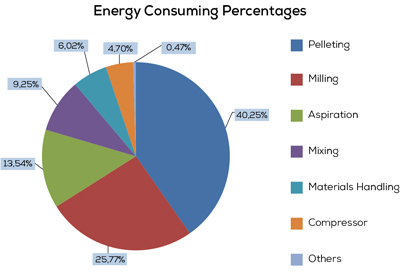

Which processes/machines have the highest energy consumption in a feed plant?Approximately 40% of electric can be consumed by pelleting line, second one is grinding line. These two lion shares are effecting system consumption. Furthermore, 80-90% of steam consumed by pelleting line. However with sifting and separate dosing lines grinding energy can be saved 10%.

What is the effect of technologies used in feed mills on electricity usage? Do current technologies really save energy?

First of all, the new electrical motors, pneumatic accessories and drive alternatives are energy saver. All producers are planning to reduce carbon footprints. However system design is the key point. Design parameters can effect whole plant’s consumes. Therefore current feed mill’s design and new investments should be checked and calculated consumption requirement power limits properly by real system experts.

How should an energy saving plan be made in a feed factory?

The improvement solutions to save energy on production processes and utilities in animal feed processing mills are numerous. The interest of these solutions must be evaluated on a case by case basis for each feed mill. Each plant must be considered as a specific case, i.e., it is impossible to generalize one case for all feed mill. The return time can vary significantly depending on investment costs, operating time of the machine, the size of the machine, the energy cost, the place, etc. Firstly need to define current consuming points with parameters of batch control or operational kW/h and separate them according to each formulation. Second step is checking the leaks and isolations. Never forget 50 tons/h capacity feed mill air compressor consume 75 kw/h and this is 5% of whole plant. It is easy to reduce it by 3% and peak it to 10% with leaks.

What needs to be done for energy saving (in terms of production planning and technological infrastructure) in feed mills?

Adjust the steam system, reduce the mass flow of the flue-gases by reducing the excess air, preheat feed-water, minimise boiler short cycle thermal losses, optimise steam distribution systems, implementing a control and repair programme for steam traps can be count on steam system.

• Managing airflow,

• Electronic speed controls,

• Highly efficient motors,

• Proper motor sizing,

• Optimizing system design,

• Variable speed drive (VSD ) and storage volume,

• Reducing compressed air system leaks and heat recovery by economizer or condenser can be top tips of energy saving key list.

We always claim that system design and equipment selection are on key role. For example the maximum efficiency is obtained for the motors working between 60 to 100% full load. The induction motor efficiency typically peaks near 75% full load and is relatively flat down to the 50% load point. Under 40% full load, an electrical motor does not work at optimized conditions and the efficiency falls very quickly. However, motors in the larger size ranges can operate with reasonably high efficiencies at loads down to 30% of rated load.

Transmission is one of the most critical point of energy savings, chain drives, belt drives, and gear drives are three main power transmission methods. Belt drives are useful when a smooth transfer of power is desired or you are looking for something that is simple, cost-effective, quieter than a chain or gear drive, or if the distance between shafts is very large. While there are many factors that can affect V-belt efficiency, by focusing on our three primary pillars Selection, Alignment and Tension. Like chain drives, gear drives are excellent for reducing or eliminating slip. They are durable, efficient, have a longer lifespan than chain and belt drives, and are very compact. However, they are not the solution to applications in which power must be transmitted over a larger distance or at a high speed. They are also not ideal if flexibility, vibration, and noise are concerns.

Can factories that have already established infrastructure and continue production save energy without making huge investments? What are the ways to do this?

It depends of technical life period of plant but without spending huge budgets system can be recovered. As Yemmak, we can provide a technical energy analysis visit and check all consumers with system flow chart, define empty loads and capacities and report them. The cheapest and maybe the free solution about energy saving is using fully limits of plant. Yemmak will provide such a consulting periods about plant controlling and long term investment planning.

Any of energy saving methods can’t save stoppage loses. Unqualified operators, inappropriate die and milling screen selections and for sure formulation can cause main stoppage and an example of pelleting section, one stoppage and restart of same formulation loses will be around 10 minutes, this means around 15% energy loses. If we manage the plants with these key points, it will be the cheapest solution.

Click to read Feed & Additive September Issue