Why is Understanding Segregation Mechanisms so Important?

In process design, the solution to a segregation problem can be attacked from two angles. The process can be modified to accommodate segregation patterns caused by the various mechanisms or changes can be made to the process to reduce the cause of segregation. In either case, understanding segregation mechanisms is critical to developing robust processes to handle segregating materials.

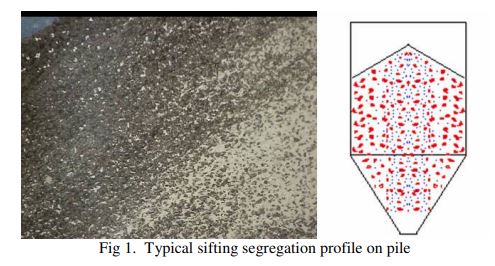

Materials segregate when handled for a variety of reasons. Many solids flow practitioners quickly identify the potential for fine material to sift through the matrix of coarse particles as material slides down a pile. Indeed, sifting segregation is a predominant cause of separation during handling of differently sized particles.

This mechanism usually results in a radial segregation pattern where fines accumulate near the center of a pile while the coarse material is predominately at the pile’s edge (see Fig 1). However, severe sifting segregation can cause a top-to-bottom segregation pattern where the fines are beneath the coarse particles. This is especially true if inter-particle motion is induced within the material by some external means such as vibration. Typically, particle size differences greater than three to one are enough to produce significant sifting segregation problems.

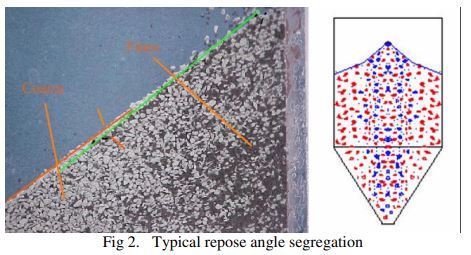

Sifting segregation is by no means the only mechanism to cause separation of particulate material during handling. Some particles have differences in inter-particle friction and thus form piles with different repose angles. Formation of piles within process equipment causes the less frictional particle to slide further down the pile accumulation at the pile’s edge. This mechanism results in a radial segregation pattern. Materials with an angle of repose difference of more than 2 degrees can show significant repose angle segregation.

The figure 2. illustrates segregation of fine and coarse fractions of roofing granules due to angle of repose. In this case, the particle size difference between the fines and coarse is only about 30% so sifting is not possible. The repose angles are only 2 degrees different and are the cause of significant segregation.

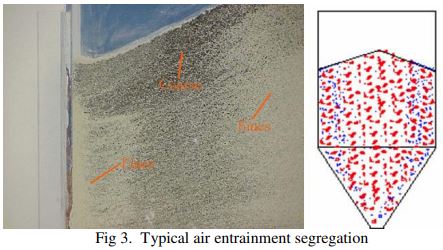

Air currents caused during filling may carry fine material to regions where the air currents decrease sufficiently to deposit the fine material. This air entrainment segregation can produce a radial pattern or a side to side pattern depending on the position of the inlet and the geometry of the vessel. Generally, fines accumulate near process vessel walls with this segregation.

Figure 3 shows a typical profile for air entrainment segregation where the fines accumulate near the wall. However, it is important to point out that this figure also shows the result of sifting segregation where the fines accumulate near the drop point. Figure 3 also indicates that several segregation mechanisms can occur at the same time producing a complex overall segregation pattern.

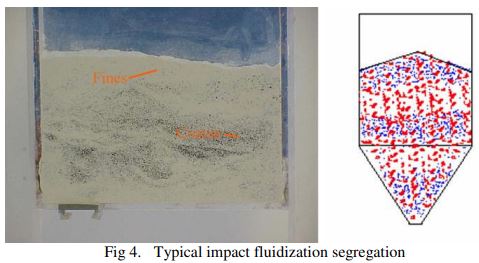

If the bulk material is very fine and compressible, then it may become fluidized during filling of a process vessel. This fluidization is not persistent as it would be in a fluid bed where there is an external source of air. The material begins to lose its entrained air soon after completion of the filling process. However, these materials retain their fluid-like behavior for several minutes or even hours.

Coarse particles entering the bin during this time can impact on this fluidized material and penetrate the top layer of fluidized solid before coming to rest below the top surface. This results in a top-to-bottom separation of particles in the bulk mixture, thereby creating layers of fines and coarse (see Fig 4).

Many solid flow practitioners promote the concept that mass flow will always solve a segregation problem. This is a short-sighted view. The flow pattern within a given piece of process equipment must be matched with the segregation profile to achieve a process that will minimize segregation during handling.

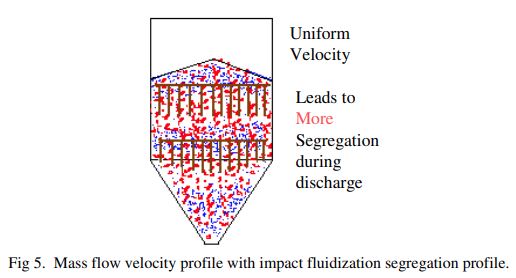

For example, suppose that the material segregated by impact fluidization forming layers when placed in a bin or a hopper. Placing a typical steep mass flow hopper on this bin would not help the segregation, but would significantly enhance the separation of bulk materials. The uniform velocity induced by a typical well designed mass flow bin would cause the coarse to exit, followed by the fines, making the segregation problem worse.

For example, suppose that the material segregated by impact fluidization forming layers when placed in a bin or a hopper. Placing a typical steep mass flow hopper on this bin would not help the segregation, but would significantly enhance the separation of bulk materials. The uniform velocity induced by a typical well designed mass flow bin would cause the coarse to exit, followed by the fines, making the segregation problem worse.

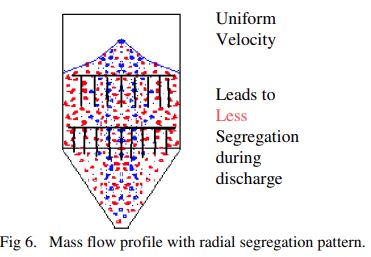

Conversely, a radial segregation pattern will be helped by converting the bin to mass flow. Material will leave the bin as it entered the hopper. There will be a segregation profile across the outlet, but at least the material at each cross-section will be the correct consistence. If better mixing than this is required, additional in-line blenders should be added to the process to achieve blend consistency.

In conclusion, knowing the segregation mechanism as well as the flow profiles in your process equipment is critical to solving potential segregation problems. Simple tests can be performed to measure the magnitude and type of segregation occurring in your systems. Flow properties can also be measured to determine the flow patterns in your process equipment. Using this information, a reliable solution to complex segregation problems can be designed to put you back on track for quality production.