With its experience in alfalfa pelleting, pellet mill technology and engineering studies, YEMMAK's alfalfa pelleting process and machine layout project required by the customer are designed, manufactured and commissioned by considering the most affordable cost.

"Alfalfa is a dried green feed that contains valuable vitamins and minerals as well as protein."

After adding a suitable binder to alfa alfas (for example, 1-3 percent molasses, oil or colloidal clays), the composition is processed under high pressure in pellet mills to form cylindrical pellets. For transport purposes, pellets generally have the same properties as the original plant residues, particularly in terms of oil and water content.

Quality / Storage Period

Alfalfa pellets are gray-green in color and differ in length and width depending on the manufacturer.

The dried green alfalfa pellets should not contain a majority of plant parts with high raw fiber content such as stems and straw, as their high raw fiber content reduces digestibility. Before they are harvested, alfalfas have higher nutritional value characterized by higher protein content.

Alfalfa pellets are primarily used as feed for livestock, horse and poultry.

Processes

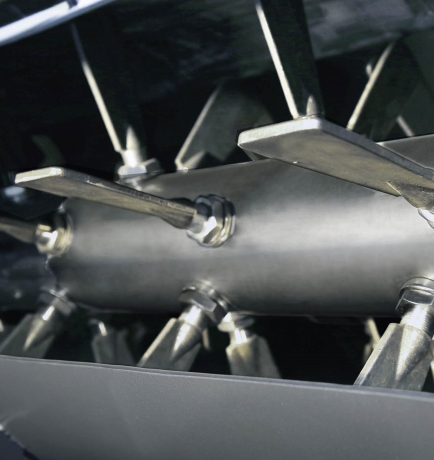

Conditioning & Hygienization

Conditioning is the step before pelleting during feed processing.

Discover

Cooling & Drying

Cooling machines produced by the Yemmak's expert engineers are used for cooling pellet feed, processed granular products, ground feed and rendered feed in the pet food facilities, chemical facilities, fertilizer production factories, and biomass

Discover

Cleaning & Sieving

During the cleaning and sieving process, foreign objects are removed from the raw material.

Discover

Conveying

Raw material transportation systems come with various types of equipment such as screw conveyors, chain conveyors and elevators.

Discover

Personalized Appointment Form

You can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time!

Industries