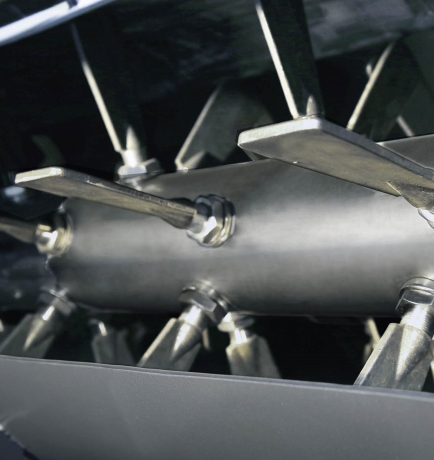

Yemmak is one step ahead in the sector by designing a special machine for wood chips pelleting with its R&D studies on the pellet mill, which is the main machine of the wood pelleting process.

Although the wood is high in volume due to its porous, irregular shape and bulky structure, its densities are low (30-150 kg/m³). When grinded, the density is increased up to 150-200 kg/m3, but it is still deemed necessary to increase its density to provide energy and ease of transportation and use. This is the reason why the wood needs to be pelletized.

"Increase Energy Efficiency with Wood Pellet"

The particle size is reduced and the total surface area is increased as a result of the process of collecting waste wood pieces and passing them through the mill for pre-grinding. Then, these powdered wood waste materials are dried in the oven and the moisture content is reduced. The dried material is finely ground and then pressed by WP series pellet mill under high pressure into pellets. The product that comes out of Yemmak pellet mill is cooled and packaged and ready for use. As a result of these processes, the burning energy efficiency of the same wood product can be increased up to 3-4 times.

Then, the pellet can provide a controlled burn. They are used in nutshell pellet stoves, stove systems using nutshell pellets, pellet stoves and pellet boilers.

As a raw material; wood (pine, larch, picea, fir etc. ), wood chips, sawdust, hull, tree branches, tree leaves and similar forest residues are used.

" Advantages of Wood Pellets"

-They are a sustainable resource

-They reduce energy imports and contribute to the national economy

-The amount of waste released to the environment after use is negligible

-They can be used to produce electrical energy

-They generate CO emissions below the threshold

- They are easy to transport and the need for storage is less compared to wood etc.

- They are manufactured from residual sawdust and similar waste materials without harming nature

Processes

Cleaning & Sieving

During the cleaning and sieving process, foreign objects are removed from the raw material.

Discover

Cooling & Drying

Cooling machines produced by the Yemmak's expert engineers are used for cooling pellet feed, processed granular products, ground feed and rendered feed in the pet food facilities, chemical facilities, fertilizer production factories, and biomass

Discover

Conditioning & Hygienization

Conditioning is the step before pelleting during feed processing.

Discover

Cooling & Drying

Cooling machines produced by the Yemmak's expert engineers are used for cooling pellet feed, processed granular products, ground feed and rendered feed in the pet food facilities, chemical facilities, fertilizer production factories, and biomass

Discover

Conveying

Raw material transportation systems come with various types of equipment such as screw conveyors, chain conveyors and elevators.

Discover

Personalized Appointment Form

You can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time!

Industries

Biomass Pelleting

Yemmak plays a major role in producing resources of biological origin, which humanity will always have a need for, and contributes to the country's economy by using these resources.

Discover