Second most consumed feed group after poultry feed, ruminant feed are produced for ruminant (cud-chewing) animals.

Although ruminants can be fed forage such as grass, various grains that are prepared in special ratios are often included in their diet as well to increase their milk yield or obtain higher yields from livestock. For this reason, grains such as wheat, corn, barley, oat and rye are of strategic importance globally. Ruminant feeds include ox, cow, cattle, calf, sheep, goat, horse, camel, pig feed, etc. example can be given. Bovine and ovine feed types can be listed as cattle feed, cattle milk feed, calf feed, buffalo feed, ovine feed, lamb feed, goat feed, sheep milk feed, sheep milk feed and goat milk feed.

The most important expense in livestock farming is undoubtedly the cost of feed. Increased incomes obtained from high-yield milk cows and beef cattle are closely related to the use of feed additives.

The better the main processes are designed for a feed mill, the better the feed quality will be. Using high-quality feed also ensures higher meat yield. All the processes that we can list, such as building the feed facility, producing the feed, and feeding the animals are interrelated. To begin and continue this process properly, an expert team must help build the facility. Feed mills built by Yemmak make this possible.

The main processes in feed mills are crushing, mixing, pelleting and bagging.

At this point, Yemmak, which has numerous experience, offers the most suitable project for the need by performing factory design and R&D studies on a customer-specific basis with its expert staff with an engineering perspective.

During the production of ruminant feeds, raw materials are turned into products after the following stages.

Processes

Cleaning & Sieving

During the cleaning and sieving process, foreign objects are removed from the raw material.

Discover

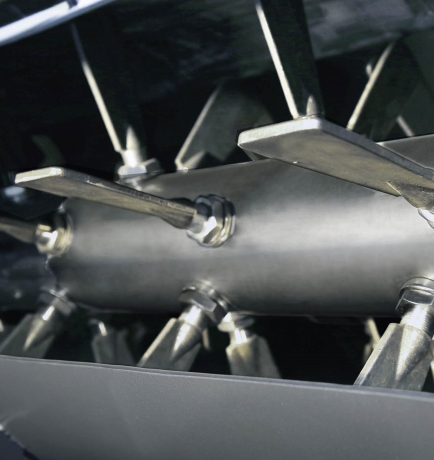

Conditioning & Hygienization

Conditioning is the step before pelleting during feed processing.

Discover

Cooling & Drying

Cooling machines produced by the Yemmak's expert engineers are used for cooling pellet feed, processed granular products, ground feed and rendered feed in the pet food facilities, chemical facilities, fertilizer production factories, and biomass

Discover

Conveying

Raw material transportation systems come with various types of equipment such as screw conveyors, chain conveyors and elevators.

Discover

Personalized Appointment Form

You can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time!

Proyem Trusts Yemmak Experience

Proyem, part of the Matlı Food Company Group, preferred Yemmak to establish a new 100 tons/hour feed mill in Polatlı, Ankara / Turkey.

The facility produces durable pellets with five pellet lines, three of which are double pelleting.

Discover

Industries